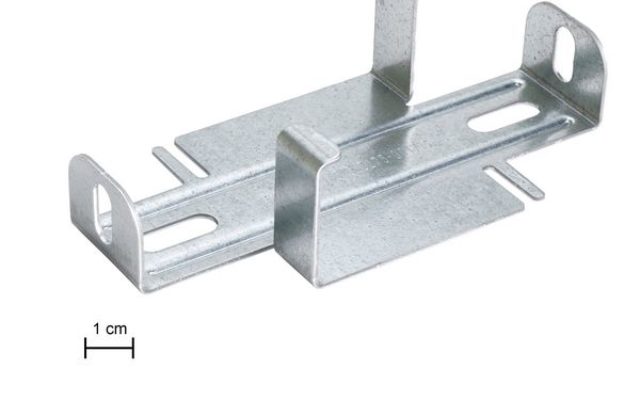

Function: Assembled part allowing the connection of an automatic transmission to the vehicle.

Material: steel DC04 thickness 2mm

Production: 250,000 pieces per year

Operations:

- Stamping the bracket into a tool to follow

- Crimping of an undercut nut (Fondex catalogue)

- Surface treatment with crimped nut (zinc plating)

- Clip-on assembly of the plastic part

Fixing Bracket: An Example of Precision Engineering

At the heart of Fondex’s production is the vehicle mounting bracket, an essential piece of engineering. This assembled part plays a crucial role in allowing the connection between the automatic transmission and the vehicle. This ensures a reliable and secure connection, ensuring the smooth operation of the transmission system.

Coated Steel: Resilient Material

A 2mm thick DC04 steel has been selected for this component, demonstrating its commitment to robustness and durability. DC04 steel is renowned for its mechanical strength and ability to withstand significant stresses. This material is a wise choice for a component subjected to considerable forces in a demanding automotive environment.

Essential Surface Treatment

The galvanizing process of the fixing bracket, with crimped nut, is a crucial step. This surface treatment is applied to protect the component against corrosion, ensuring its durability in varied conditions. This zinc layer provides an effective barrier against external elements, ensuring that the bracket remains reliable and functional throughout the vehicle’s lifespan. Fondex, with its expertise and commitment to quality, contributes to the safety and performance of automotive vehicles.