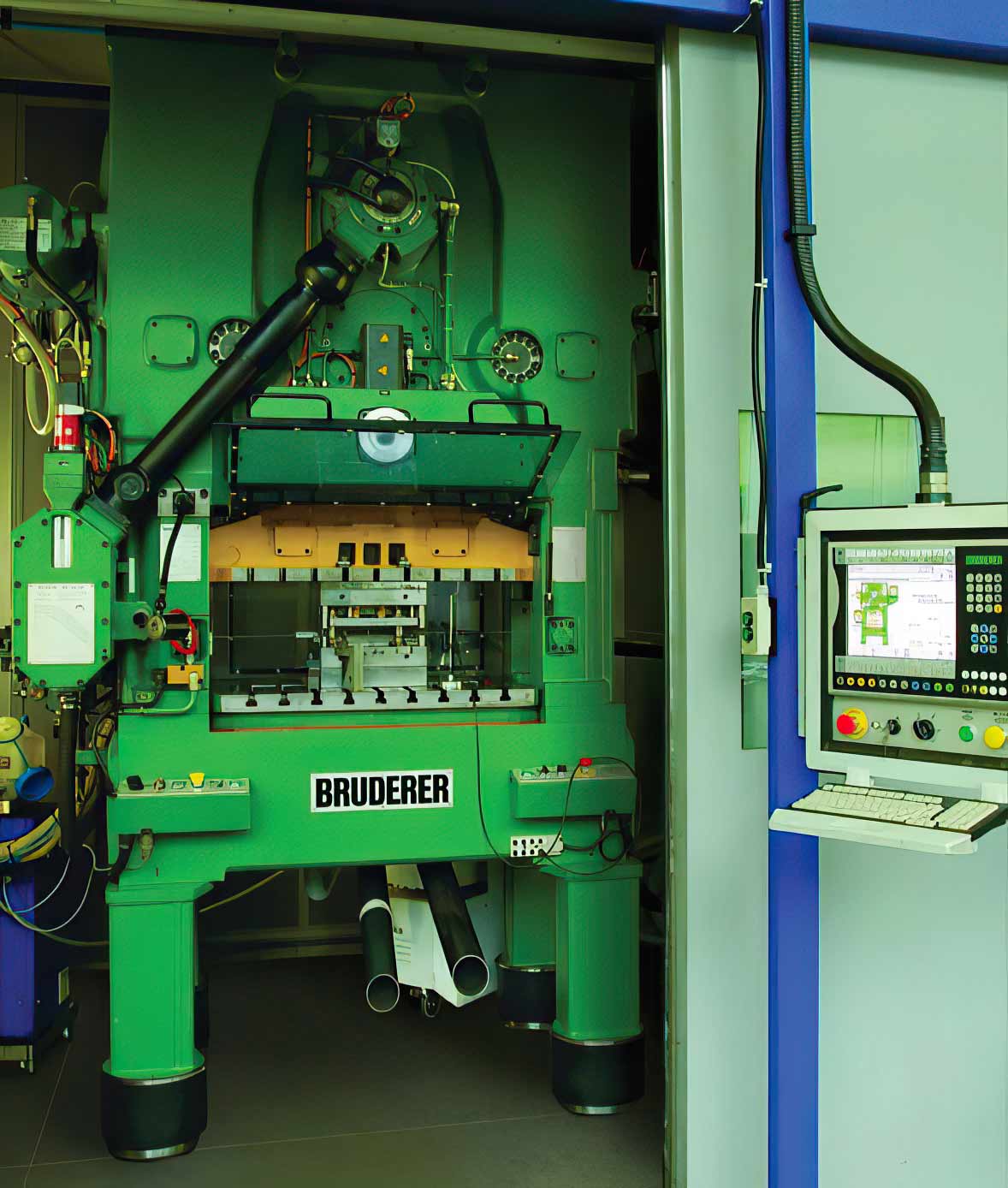

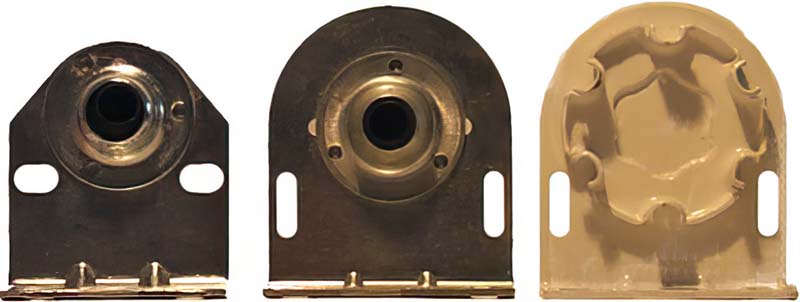

Mechanical part stamping

We have not stopped developing on our cutting experience since the company opened in 1954. Our expertise in all components, from the simplest to the most complex, and in all types of manufacturing, has provided us with a unique knowledge base and put us in the lead in high-requirement industries like: automobile, defense, security, aeronautics, railway, electronics…

Plan analysis

Range definition

Tools design

Manufacturing & optimization

OUR KNOW-HOW IN STAMPING

Design and development of stamped components

Definition of specifications, value analysis, band width and pitch optimization

Research on a range of stamping products

Research on the optimal number of stations, development of in-line settings, optimization of the number of prints to respond to cost-efficient and technical restrictions

Tool production in the integrated mechanical workshop

Prototyping and batch series of stamped parts

Mass production with on-site JIT delivery

Operations on stamped parts: deburring, degreasing, tumbling

Finishes, assembly, packaging and a possibility of selective coatings before or after stamping

TECHNICAL CHARACTERISTICS

- Thickness of stamped sheet metal: from 0.01 to 6 mm

- Press tonnage: up to 400 tons

- Technologies: compound die, blanking die, progressive die, transfer die, rework dies, tapping

- On press machines and cam stations

- Press capacity: maximum bed length: 2500 mm

- Stamped materials: coated steel, stainless steel, heat-resistant stainless steel, aluminum, brass, copper, bronze, nickel

STAMPING SPECIALITY

Stamping pre-machined or pre-coated strips to avoid rework operations and aim for cost-savings