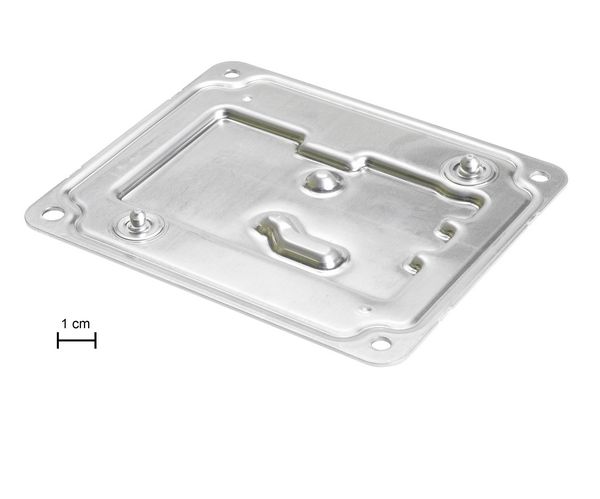

PCB mounting plate

PCB mounting plate

Function: Electronic calculator component for automotive LED headlights.

This part allows the fixation of the printed circuit, the waterproofing of the computer and the heat dissipation.

Material: aluminium 5754 thickness 1.5 mm

Production: 1,600,000 pieces per year

Operations:

- Progressive die stamping

- Welding of pins (robotic cell)

- 100% leakage control

- Dépollution particulaire

- Surface tension and particle control (size and number)

- Packaging in clean room

Fastening, Sealing, and Heat Dissipation: Versatile Functionality

The printed circuit board mounting plate plays a central role in the electronic controllers of automotive LED headlights. It ensures secure fastening of the printed circuit board, ensuring reliable operation while providing essential sealing to protect sensitive electronic components. Additionally, it contributes to efficient heat dissipation, maintaining an optimal temperature for the controller’s operation.

Aluminium 5754: A Durable Material

The mounting plate is manufactured from 1.5mm thick aluminium 5754, offering both lightweight and durability. This ensures that the piece withstands rigorous environmental conditions while maintaining its structure and performance over time.

Quality and Control

Fondex distinguishes itself through its commitment to quality and precision. The manufacturing process includes progressive die stamping, pin welding performed by a robotic cell, and meticulous quality control, ensuring impeccable sealing. Additionally, cleanroom treatment guarantees that the piece is free from polluting particles, thus meeting the industry’s strictest standards.